Mutsetse wekugadzira magaba eAutomatic10-25L ane denderedzwa rakatenderera

Mutsetse wekugadzira magaba eAutomatic10-25L ane denderedzwa rakatenderera

Mhinduro yemapoto esimbi

Mapaipi esimbi ane denderedzwa resimbi anogona kugadzika, kugara kwenguva refu, uye machira akagadzirwa nehunyanzvi senge epoxy-phenolic kudzivirira ngura, uye anoshandiswa mumaindasitiri akadai sekupenda, makemikari, chikafu, uye kurongedza mishonga.

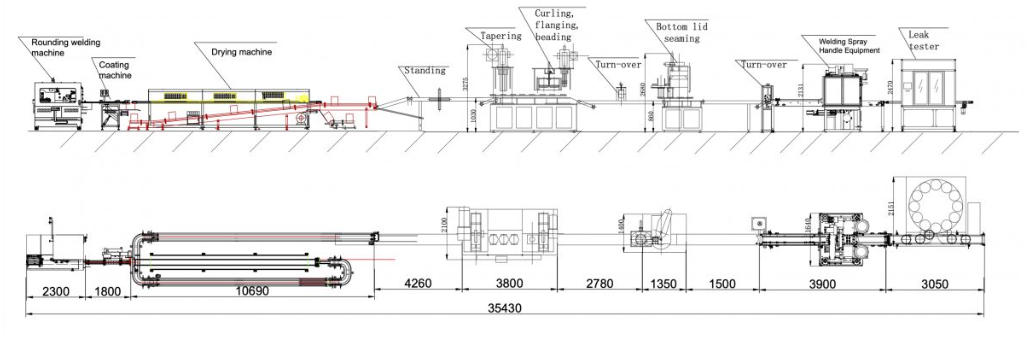

10- mutsetse wekugadzira mapani esimbi

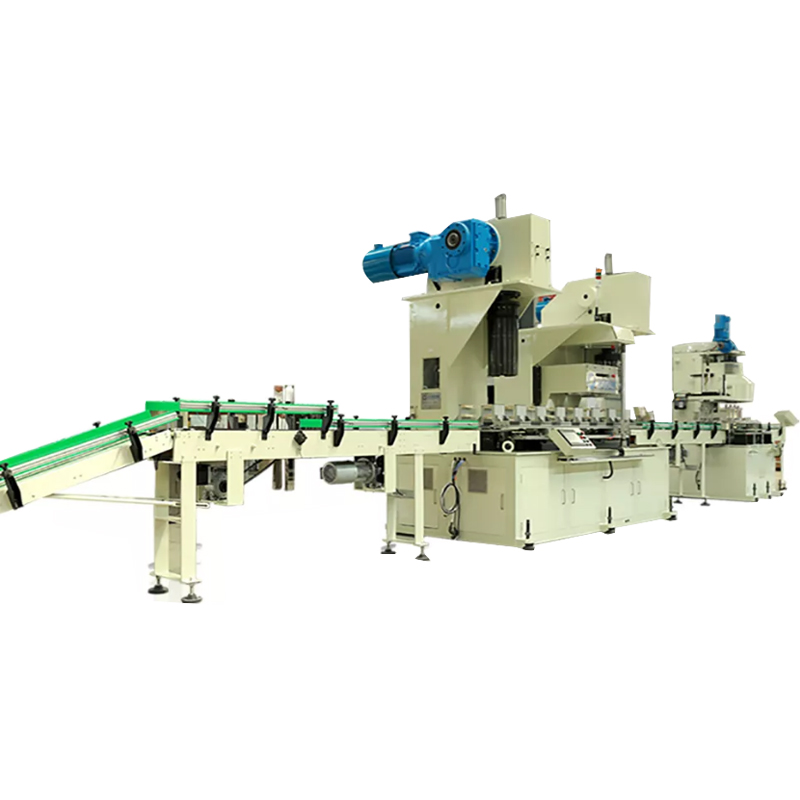

Iyi kani yekugadzira mutsetse ndeyeyakagadzirirwa kugadzirwa otomatiki of 10-25L ndiro yekongiri,

iyo inoumbwa nendiro nhatu dzesimbi: muviri wegaba, unogona kufukidza uye pasi pegaba. gaba racho rakaita sedenderedzwa.

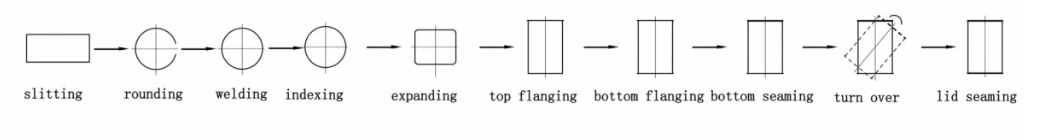

Kuyerera kwehunyanzvi:

1. Kucheka pepa resimbi kuti rive risina chinhu

2. Kutenderedza & Kushongedza

3. Kupfeka kwemukati nekunze (kupfeka kwemukati nekunze)

4. Kuomesa & Kutonhodza kutakura

5. Kuisa Flanging muConical & Kuwedzera

6. Kuputira, Kukombama, Kushongedza

7. Kudyisa chivharo chepazasi

8. Kusona

9. Kutendeudza

10. Kubatanidza makumbo enzeve & coating & mubato weupfu

11. Kurongedza bvunzo dzekudonhedza mvura

Otomatiki denderedzwa kani kugadzirwa mutsetse

Iyi kani yekugadzira mutsetse ndeyeyakagadzirirwa kugadzirwa otomatiki of 10-25L ndiro yekongiri,

iyo inoumbwa nendiro nhatu dzesimbi: muviri wegaba, unogona kufukidza uye pasi pegaba. gaba racho rakaita sedenderedzwa.

Kuyerera kwehunyanzvi:

1. Kucheka pepa resimbi kuti rive risina chinhu

2. Kutenderedza & Kushongedza

3. Kupfeka kwemukati nekunze (kupfeka kwemukati nekunze)

4. Kuomesa & Kutonhodza kutakura

5. Kuisa Flanging muConical & Kuwedzera

6. Kuputira, Kukombama, Kushongedza

7. Kudyisa chivharo chepazasi

8. Kusona

9. Kutendeudza

10. Kubatanidza makumbo enzeve & coating & mubato weupfu

11. Kurongedza bvunzo dzekudonhedza mvura

Zvakanakira zvemuchina wekugadzira mapaipi ane denderedzwa:

1. Furemu yesimbi inorema yakaputirwa nesimbi isingatsvi yakabatana nefuremu yechubhu inoita kuti muchina ugare kwenguva refu, wakasimba uye wakavimbika.

2. Sisitimu yekutumira michina inoita kuti ikwanise kushanda kwehupenyu hwese pasina kugadziriswa kwakawanda.

3. Kubatanidza kupeta kwepamberi pekukombama, kukwenya, uye kupeta kwemativi.

4. Dhizaini diki inoderedza uye inochengetedza nzvimbo inokosha.

5. Kushanda kunoitika otomatiki zvizere uye kushanda zvakanaka uye kugona.

6. Muchina uyu unogona kugadzira magaba esimbi ane saizi dzakasiyana nekuchinja maturusi.

7. Kudzora kwePLC uye interface yeHMI yekubata skrini inonzwisisika kuti ive nyore kugadzirisa.

8. Sisitimu yekuongorora zvikanganiso inodzivirira muchina kubva mukukuvadzwa.

9. Sisitimu yemafuta otomatiki *Alarm otomatiki

10. Muchina uyu unogona kushanda wega kana kuti unogona kuiswa mumutsetse wako uripo.

Muchina wekugadzira mabhaketi esimbi weChina unoshandiswa kugadzira 10-25L denderedzwa resimbi, mabara, madhiramu, mabhaketi, zvakaita sependi, mafuta, mapairi eglue. Kana uchida kugadzira mabhaketi akadaro saizi dzakasiyana, unongoda kuchinja maforoma emuchina. Saizi yebhaketi inogona kugadziriswa zvichienderana nezvaunoda.

Maitiro ekushanda

▶Chekutanga isa zvinhu zvemukati zvechigaba chakachekwa patafura yekudyisa yemuchina we automatic resistance welding, sveta ne vacuum suckers, tumira mablanks etinini ku feeding roller imwe neimwe. Kuburikidza ne feeding roller, tin blank imwe chete inopihwa ku rounding roller kuti iite rounding process.

▶Ipapo ichaiswa muchimiro chekukombamisa kuti iite rounding. Muviri unoiswa mumuchina wekukombamisa we resistance uye wobva wagadzira welding mushure mekuiswa kwayo zvakanaka.

▶Mushure mekusanganisa, muviri wegaba unoiswa otomatiki muchina unotenderera wekugadzira magineti wemuchina wekusanganisa magineti wekunze, wemukati kana wemukati weupfu, zvinoenderana nezvinodiwa nemutengi. Unonyanya kushandiswa kudzivirira kuti mutsetse wekusanganisa magineti wedivi usaburitswe mumhepo uye kuti uparare.

▶Mutumbi wegaba unofanira kuiswa muovheni yekuomesa yeinduction kuti uome kana uri wemukati kana wemukati weupfu. Mushure mekuomesa, rinoiswa mumudziyo wekutonhodza kuti ritonhodze zvechisikigo.

▶Muviri wegaba rakatonhodzwa unozopihwa kumuchina wekubatanidza ndiro ine denderedzwa, uye muviri wegaba unenge wakamira zvakanaka uchipinda nemuchina wekutakura wakamiswa.

▶Kushanda kwekutanga ndiko kuwedzera ganda remugaba. Kana muviri wegaba uri panzvimbo, patireyi yekusimudza muviri wegaba iyo inodzorwa nemota yeservo, uye muviri wegaba unotumirwa netireyi iyi yekusimudza kuenda kumould iri kuwedzera ganda kuti ikure ganda.

▶Danho rechipiri nderokuputira jira rekutanga Danho rechitatu nderokuputira jira. Chiumbwa chepamusoro chakasungirirwa pamuviri wemuchina, uye chiumbwa chepazasi, chakaiswa paCAM, chinopedzisa kuputira jira nekuputira jira kana CAM yaiswa mudenga. Danho rechina nderokuputira jira.

▶Mushure mekupedza matanho mana ari pamusoro apa, kana chivharo chepazasi chaona kuti chivharo chiri kuuya, chinozoisa chivharo chimwe chete pamusoro pechivharo, uye ipapo chivharo chepazasi nepazasi zvinosungirirwa pamusoro pemuchina wekusona kuti zviite zvekusona otomatiki.

▶Mushure mekusona pasi, inopihwa muchina wekusonwa nzeve une mapoinzi maviri otomatiki, kuburikidza nekuiswa kwesero repadivi otomatiki, Cam conveyor conveyor, kupwanya pendi yemakanika, inewo madhisiki anodedera ear lugs otomatiki, kupedzisa basa rekusonwa rakanyatsonaka pabhawa reconical.

▶Zvadaro, ndiro yacho inopihwa kuti igadzire mubato uye nzvimbo yekusangana kuti ipedzise mubato wega.

▶Chekupedzisira, gaba rapera rinoendeswa kunzvimbo yekuyedza kudonha kwemvura otomatiki neconveyor.

Kuburikidza nedanho rakarurama rekuona mhepo, zvigadzirwa zvisina kukodzera zvichaedzwa uye zvichapihwa kunzvimbo yekugadzirisa. Mapoto akakodzera achauya patafura yekurongedza kuti apedziswe.

Musanganiswa wemidziyo yemagaba akatenderera ekugadzira otomatiki

| Kucheka kwekutanga (upamhi hwemaminitsi) | 150mm | Kucheka kwechipiri (min upamhi) | 60mm |

| Kumhanya (zvipenga/min) | 32 | Ukobvu hwepepa | 0.12-0.5mm |

| Simba | 22kw | Voltage | 220v/380v/440v |

| Huremu | 21000kg | Chiyero (L*W*H) | 2520X1840X3980mm |

| Muenzaniso | CTPC-2 | Voltage & Frequency | 380V 3L+1N+PE |

| Kumhanya kwekugadzira | 5-60m/miniti | Kushandiswa kweupfu | 8-10mm & 10-20mm |

| Kushandiswa kwemhepo | 0.6Mpa | Kugona kwemuviri | D50-200mm D80-400mm |

| Mhepo inodiwa | 100-200L/miniti | Kushandiswa kwesimba | 2.8KW |

| Chiyero chemuchina | 1080*720*1820mm | Huremu hwese | 300kg |

| Rudzi rwemafrequency | 100-280HZ | Kumhanya kwekushongedza | 8-15m/miniti |

| Kugona kugadzira | 25-35Makani/miniti | Dhayamita yegaba rinoshanda | Φ220-Φ300mm |

| Kureba kwegaba kunoshanda | 220-500mm | Zvinhu zvinoshanda | Tinplate, yakavakirwa pasimbi, Chrome plate |

| Ukobvu hwezvinhu zvinoshanda | 0.2~0.4mm | Dhayamita yewaya yemhangura inoshanda | Φ1.8mm ,Φ1.5mm |

| Mvura inotonhorera | Tembiricha: 12-20℃ Kumanikidzwa:>0.4Mpa Kuyerera: 40L/min | ||

| Simba rose | 125KVA | Chiyero | 2200*1520*1980mm |

| Huremu | 2500Kg | Upfu | 380V±5% 50Hz |

| Kureba kwenzvimbo yehuni | 50-600mm | dhayamita yedhayamita | 52-400mm |

| Kumhanya kweroller | 5-30m/miniti | Rudzi rwekuputira | Kuputira kweroller |

| Upamhi hweLacquer | 8-15mm 10-20mm | Kupa kukuru & Mutoro wezvino | 220V 0.5 KW |

| Kushandiswa kwemhepo | 0.6Mpa 20L/min | Chiyero chemuchina & Huremu hweNet | 2100*720*1520MM300kg |

| Simba remoto | 1-2KW | Kumhanya kwekupisa kweburner | 4m-7m/miniti |

| Yakakodzera dhayamita diki yekani | Φ45-Φ176mm | Yakakodzera dhayamita hombe yekani | Φ176-Φ350mm |

| Kureba kwekabati | 45mm-600mm | Mvura inotonhorera | >0.4Mpa, 12-20℃,40L/min |

| Kushandiswa kwemhepo | ≥50L/min>0.5Mpa | ||

Sisitimu yekubatanidza muviri wegaba otomatiki

| Kukwanisa kugadzira | 25-30cpm | Mhando yemagaba eDia | 200-300mm |

| Kureba kwegaba | 170-460mm | ukobvu | ≤0.4mm |

| Simba rose | 44.41KW | Kumanikidzwa kwesistimu yepneumatic | 0.3-0.5Mpa |

| Saizi yekutakura zvinhu yakamiswa nemuviri | 4260*340*1000mm | Saizi yemuchina wekusanganisa | 3800*1770*3200mm |

| Saizi yekabhoni yemagetsi | 700*450*1700mm | Huremu | 9T |